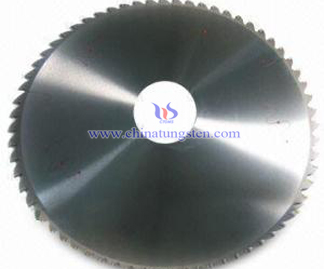

Tungsten Carbide Saw Blades

The classification of tungsten carbide saws:

Tungsten carbide saws can be mainly divided into tungsten carbide saw tips,tungsten carbide saw blades and tungsten carbide hole saws.

Tungsten carbide saw blades:

Tungsten carbide saw blades are used for the manufacture of inlaid carbide saw with a variety of specified carbide grades for different selections.

The advantage of tungsten carbide saw blades:

Provides long life due to their super resistance to heat, wear, and abrasion.;

Resist snagging while working on hard-to-cut materials;

Specifications include both continuous or gulleted edges and various grit sizes;

Use coarse grit for faster cutting of thick materials or metals;

Use medium grit for thin materials and fine finishes;

Continuous grit: For 1/4" (6.4mm) or under wall cross-section. Also good for brittle materials or if surface may chip;

Gulleted grit: For 1/4" (6.4mm) or larger wall cross-section;

How to make the tungsten carbide saw blades?

Normally, there are two ways to use tungsten carbide to make saw blades.

Tungsten carbide tipped saw blades: The saw blades' teeth are tipped (via welding) with small pieces of sharp tungsten carbide block. Tungsten carbide tipped saw blades are widely used to cut wood, plywood, laminated board, plastic, grass, aluminum and some other metals.

Tungsten carbide saw blades: The whole saw blade is made of tungsten carbide. Comparing with HSS saw blades, solid carbide saw blades have higher hardness under high temperatures, and are more durable, but they also have a lower toughness.

The application of tungsten carbide saw blades:

For slotting in the spectacles frame's industry;

For computer hard disk head industry;

For cutting/scoring the pcb board;

For artificial crystal slotting/cutting;

For jewellery (gold, silver, copper), accessory industry;

For metal (alloy) precise cutting/slotting;